Solutions:

Alternative Floor Surfaces

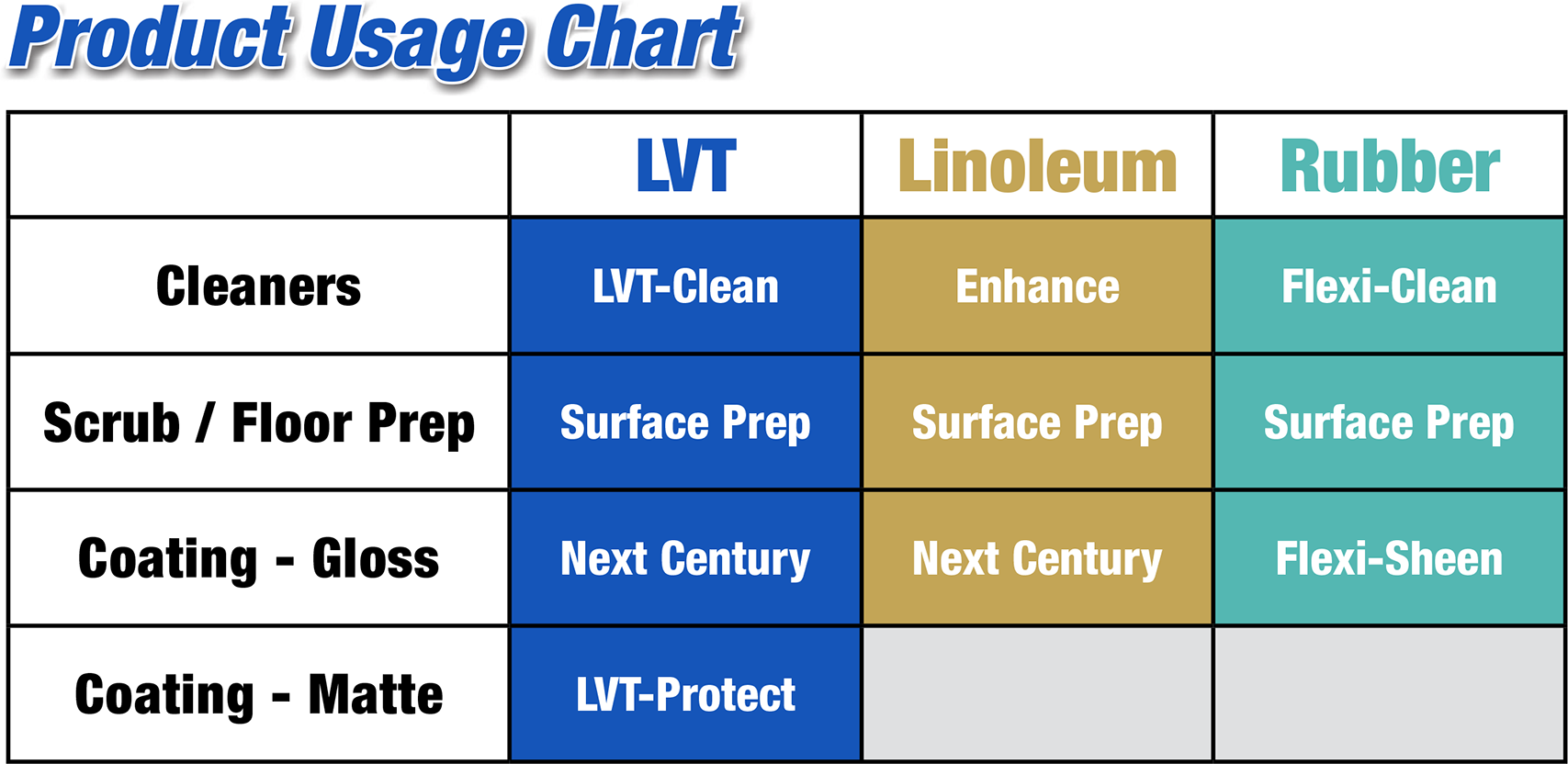

Solutions for Linoleum, LVT & Rubber Floors

Alternative flooring surfaces in commercial facilities are drastically increasing in popularity. Whether it is a classic material undergoing a renaissance of popularity like linoleum, a common material finding new uses like rubber, or a new innovation like Luxury Vinyl Tile; these alternative surfaces are here for the foreseeable future.

In today’s environment, maintenance staffs must be able to identify these surface types and recognize their characteristics and how those characteristics require different maintenance methods than they may be used to with traditional vinyl and VCT flooring.Linoleum

Linoleum flooring is a type of resilient flooring made from natural raw materials, such as linseed oil, cork or wood flour, pine resin, ground limestone, and natural pigments. These materials are not only durable, but they are renewable, biodegradable, and have minimal environmental impact. The eco-friendly composition and durability are two major factors in the resurgence of this flooring material.

While many remember linoleum from extensive use in residential construction, these days the use of linoleum is rapidly expanding in commercial buildings. Linoleum offers some degree of resilience under-foot, supplying a comfortable surface to walk or stand on while working. It is resistant to scratches, dents, and wear, making it ideal for use in high traffic areas. From a design standpoint, linoleum offers a wide range of color, pattern, and style options for extensive design versatility. Many facilities can replicate the appearance of hardwood, stone, or tile flooring without the extensive and expensive maintenance obligations those surfaces require.

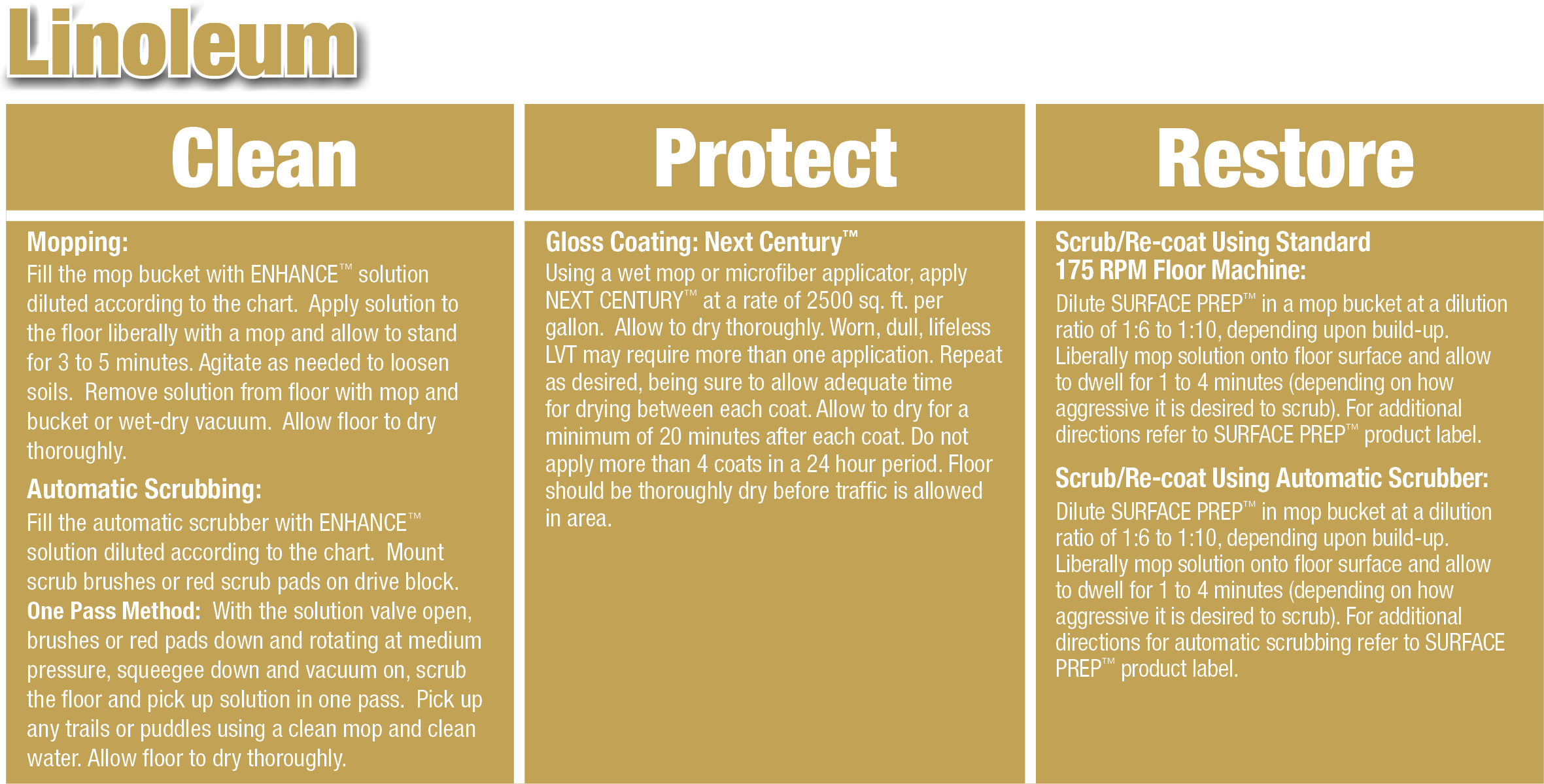

The maintenance of linoleum is not as extensive as other types of surfaces, but the all-natural composition is sensitive to some products widely used in the maintenance of vinyl flooring materials.

Typical water-based acrylic floor finishes will not harm linoleum surfaces. However, the strippers that need to be used when the finish has concluded its life cycle can cause extensive damage to linoleum floors. The chemical components of floor strippers can damage linoleum’s protective coating and penetrate the porous surface. That will likely alter its appearance, cause discoloration, affect the natural finish, and create an uneven appearance.See our Linoleum Care Solutions!

Luxury Vinyl Tile

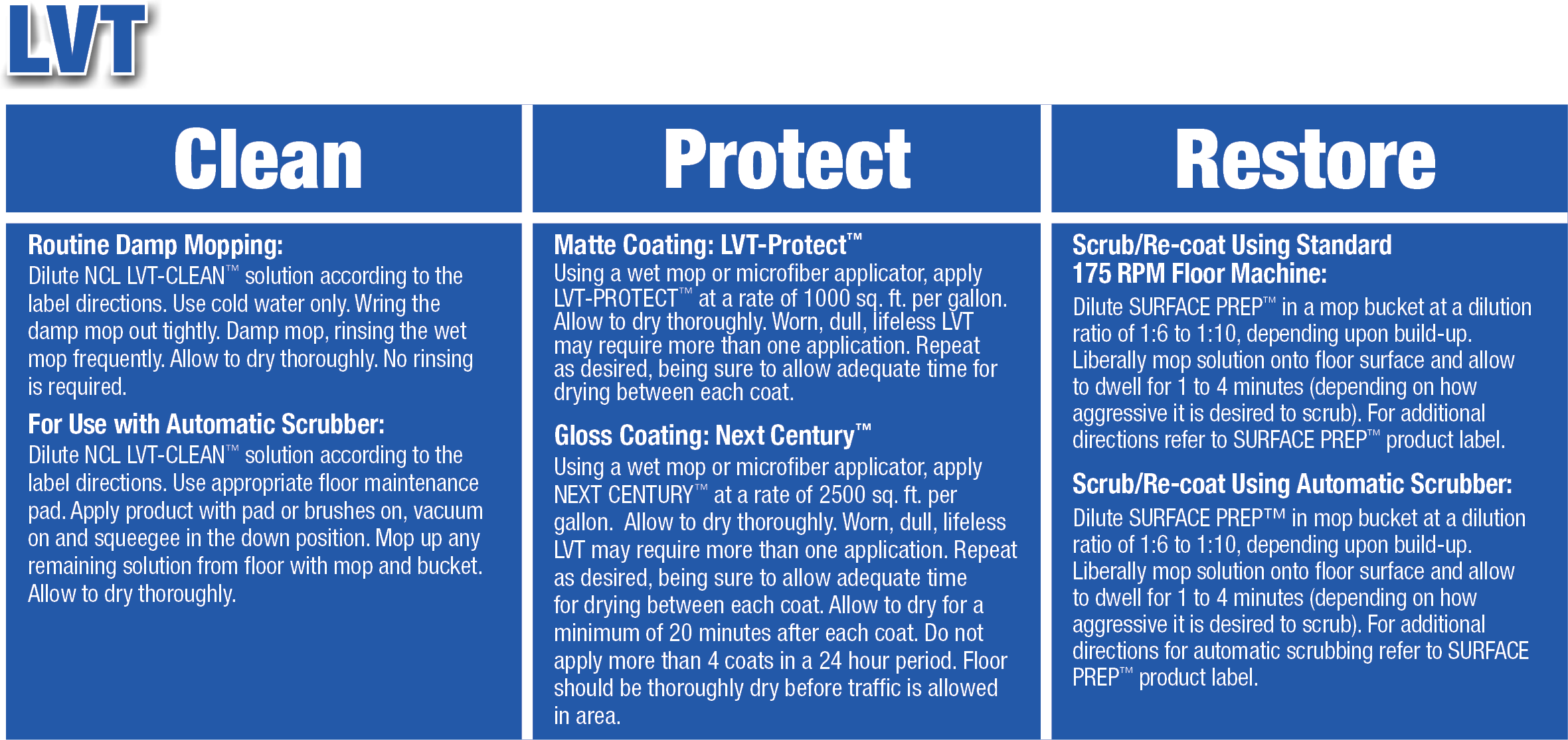

A new arrival on the alternative flooring scene is Luxury Vinyl Tile (LVT). LVT is a type of resilient flooring that has gained popularity for its versatility, durability, and aesthetic appeal. LVT is designed to mimic the look of tile or natural materials such as wood or stone while offering several practical advantages. These flooring surfaces are waterproof and resistant to scuffs, scratches, dents, stains, and wear.

Similar to linoleum and rubber flooring, LVT provides a high level of under-foot comfort. In comparison to true tile, wood, or stone, LVT floors are more comfortable and less stressful for those who stand or work on these floors for extended periods of time. In many instances, the maintenance is less extensive and labor intensive than true tile, wood, or stone surfaces.

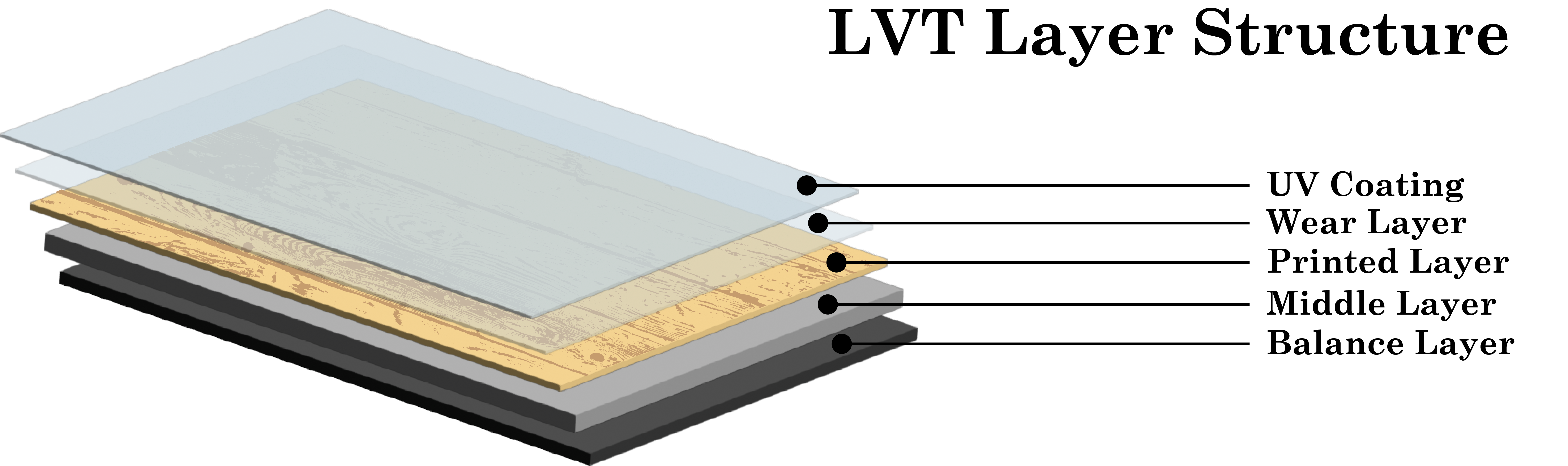

LVT is comprised of multiple layers:

- UV COATING – top layer, provides resistance against fading and discoloration caused by exposure to ultraviolet (UV) light from the sun or artificial light sources.

- WEAR LAYER – safeguards against scratches, stains, wear, and other types of damage from foot traffic and everyday use.

- PRINTED LAYER – mimics the appearance of natural materials like wood or stone through advanced printing technologies which can simulate realistic textures and details.

- MIDDLE LAYER – provides stability and durability.

- BALANCE LAYER – bottom layer, adds strength and stability.

Like linoleum, it is not advisable to apply traditional floor finish to LVT due to the extensive damage that can occur when applying stripper to remove the finish. The harsh chemicals or solvents in a floor stripper can penetrate the UV coating and wear layer, causing extensive and permanent damage to the printed design layer.

See our LVT Care Solutions!Rubber Flooring

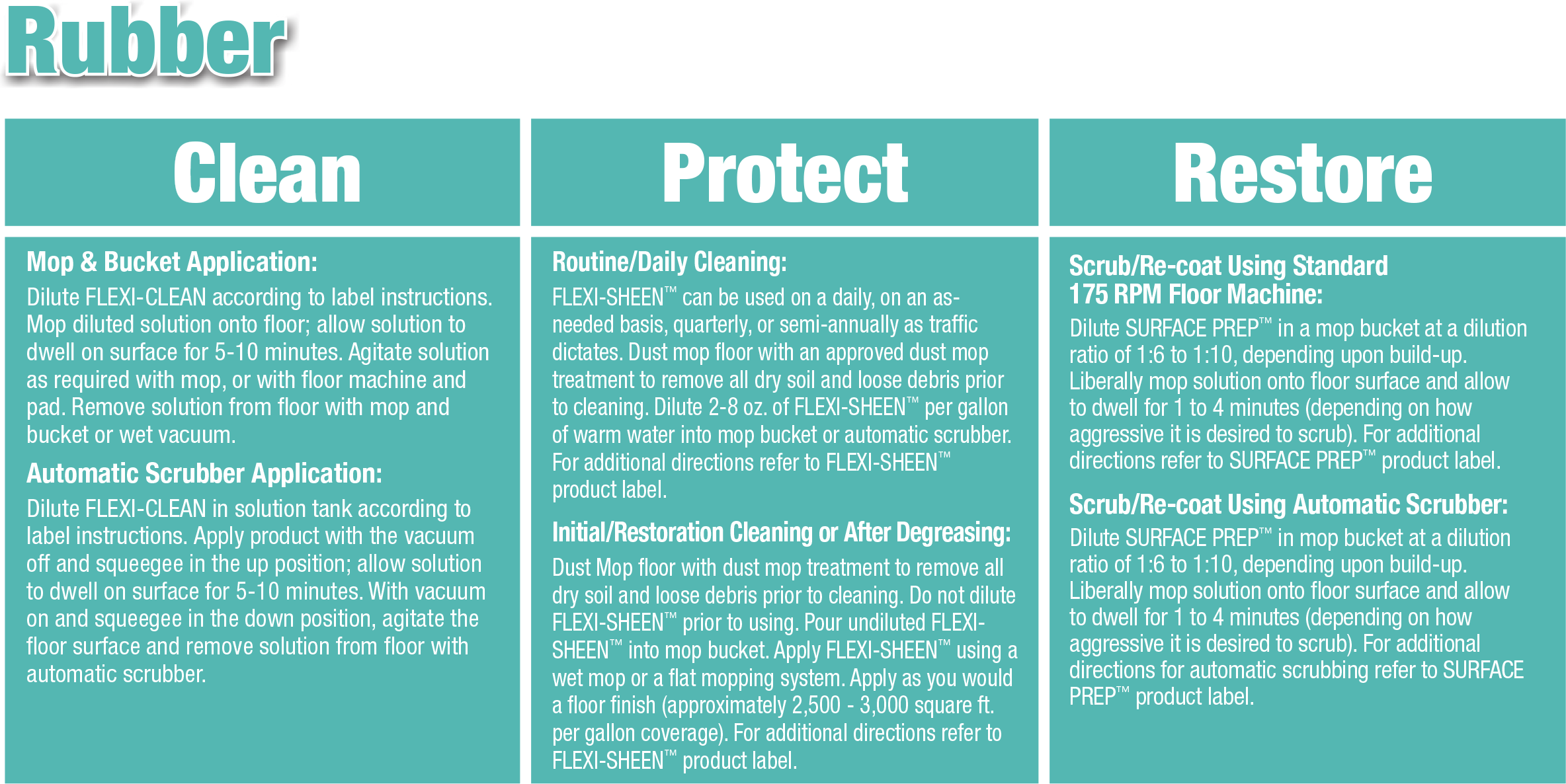

Rubber floors are more popular than ever in commercial facilities for their ability to absorb heavy impact and increase safety, reduce noise, increase comfort for those standing for pro-longed periods of time, and resistance to stains, moisture, some chemicals, scuffs, scratches, mold, and mildew.

Many schools, especially elementary schools, are installing rubber sport floors. They have found, in many cases, compared to vinyl or wood sport floors, rubber floors with their shock absorption properties are much safer for children. The rubber floors also contain natural sound absorption properties to help maintain a conducive learning environment in classrooms near the physical education areas. Rubber floors also supply schools with an eco-friendly option that is highly durable, customizable, and cost effective.

Rubber floors have long been found in fitness centers in free weight areas. These surfaces absorb the impact of dropped heavy weights, reduce noise, and provide a comfortable under-footing. Those characteristics are now seen as more applicable in other types of facilities, such as in healthcare and retail sectors, where safety and comfort are highly valued. Rubber flooring’s hypoallergenic properties and resistance to mold and mildew are another factor in the increasing popularity in healthcare, long term/elder care, and other related facilities. The unique characteristics of rubber floors present a multitude of obstacles for coating and protecting the surface. Rubber floors can have slight movements or flexibility, especially in areas with temperature fluctuations or heavy traffic. This movement can cause a floor finish to crack or break over time. The differences in texture and composition of the rubber surface will also present a hindrance to adhesion of a floor finish. Also, many finishes may be chemically incompatible with the components that comprise a rubber surface, leading to unpredictable adhesion.See our Rubber Floor Care Solutions!

Where to find these surfaces

Linoleum is no longer just found in residential kitchens from the 1970’s. Linoleum is in the midst of a 21st century resurgence in commercial facilities. The durability, ease of maintenance, and aesthetic options make this a popular option in healthcare, educational, office, retail, hospitality, municipal, and religious facilities. The stain resistance of the surface also appeals to educational and hospitality environments. The antimicrobial properties of linoleum appeal to healthcare facilities and laboratories.

Likewise, those same types of facilities are also where LVT flooring is increasing in popularity. The technological advancements with LVT produce surfaces that replicate “high end” surfaces such as natural polished stone and natural hardwood for a fraction of the price with a much greater ease of maintenance.

Rubber flooring has long been found in the form of studded rubber on staircases to increase slip resistance. The outstanding ability to absorb a high level of shock has long made rubber floors an optimal choice in gyms and health clubs where dropped weights would damage most other surfaces.

Many schools have moved away from hardwood sports floors in their gymnasiums and opted for rubber floors. They find that rubber surfaces are less expensive and easier to maintain. The shock absorption properties make the floors safer for children with reduced injury risks. Rubber floors also absorb sound, helping to keep classrooms near the gyms quiet.Restaurants, cafeterias, food processing areas, retail locations, and other facilities with commercial kitchens are choosing rubber floors for its resistance to water, grease, and stains. The improved traction and slip resistance increase worker safety.

Those environments along with others where people are expected to stand for pro-longed periods are finding that natural cushioning properties of rubber, in addition to supplying superior shock absorption, also reduce the impact on joints and muscles for those standing for extended periods. The elasticity of and resilience reduce fatigue, helping to reduce discomfort and fatigue, and increase productivity.

How to maintain these surfaces

While the manufacturers of these flooring materials tout their ease of maintenance in comparison to other types of floors, facilities must be aware that the unique characteristics that make these surfaces ideal flooring options also require specialized products designed specifically for these unique surfaces.

English

English Español

Español